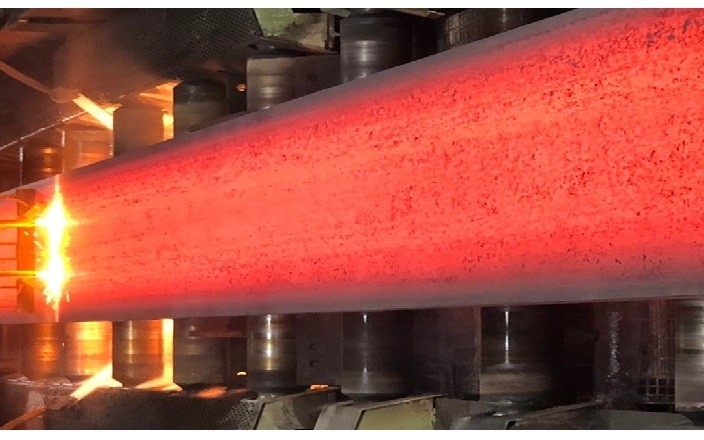

Mould Level Control

MLC Mould Level Control global up-grade approach

+ Data collection including site survey,

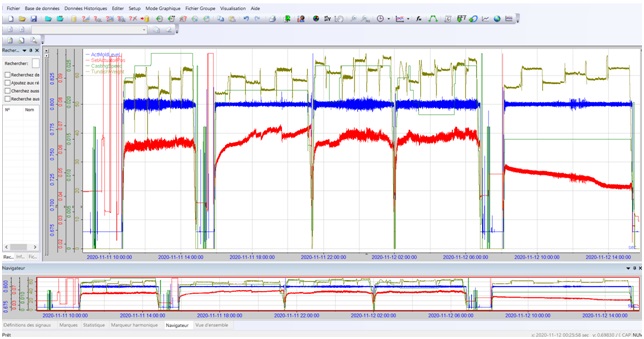

+ Existing MLC performances evaluation,

+ MLC components check & rank :

- Flow control refractories,

- Stopper / Tundish Gate actuator,

- Level Controller method and settings,

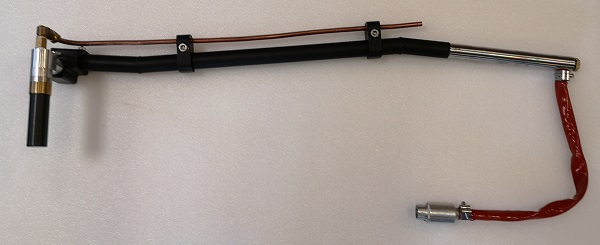

- Mould Level sensor.

+ Recommandations and solutions proposal.

+ Performances improvement guarantee.

MLC Trends Analysis

WHY CONDUCTING A MLC GLOBAL AUDIT WITH E-NOTEX ?

- I have steel surface quality problems,

- I have casting accidents from time to time : mould overflows, break-outs, sequence breaks ...

- I observe periodical mould level disturbances quite often,

- I observe mould level surges quite often,

- I have a high maintenance rate of my MLC components : sensor, stopper mechanism, stopper actuator ... ,

- I have obsolescence concerns about my MLC components,

- I don't know if my MLC system performances are optimal,

- I don't have time or experience to deeply dig into MLC subject,

- I'd like to get benefit of highly professionnal specialists with more than 25 years of experience with MLC,

- I prefer to run an independant evaluation prior to consider any big equipment up-grade investment.

If you reply yes for some to the below questions, feel free to contact us, we can evaluate free of charge if a MLC audit makes sense.

Repairs & Spare Parts

Sensor Processing Unit Board Spare

NO THROW AWAY if REPAIRABLE !

E-NOTEX policy is to provide the best long term service to its customers after the comissionning of the equipment. E-NOTEX provides a free of charge repair estimation to every faulty component received, to be approved by the sender.

SPARE PARTS

Exceeding the industry standart, E-NOTEX commits to provide spare parts for a minimum duration of 12 years after supplying a system.

OTHER VENDORS SPARES

E-NOTEX is capable to provide most of the mould level sensor vendors components, including sensor heads, cables, processing units ... This allows to deal with obolescence, cost reduction and sensors quality improvement without replacing the whole system.

Feel free to contact us for a technical proposal and quote !

Hi Temp Sensor Cable Spare